Main Products: Heat Exchange and Process Equipment

All of our units are custom-made: engineered and produced bespoke according to the particular process requirements.

Listed below are exemplary main products whose components (such as steam or water heaters, sorption wheel, electric air heater, filters, etc.) are being combined as needed according to the process requirements - to achieve the best economic efficiency and sustainability.

See the photographs shown at the end of this page and get impressions about our high quality products being used worldwide.

Finned Tube Solutions, Process Air Treatment and Heat Recovery

STEAM HEAT EXCHANGERS

Finned tube heat exchanger type using steam to heat up gaseous media.

Air Intake Units

Unit for ambient air treatment according to the clients process demands.

Desiccant Dehumidifiers

Unit to dehumidify process air applying a dessicant (sorption) wheel.

Cooling Dehumidifiers

Air dehumidification by condensation, using ice water or other cooling media.

Electrical HEAting units

Unit to heat up gaseous media with heating rods using electricity as energy source.

AIR Handling UNITS

Unit for process air handling according to our clients process demands.

High AIR Pressure Units

Unit for handling pressurized process air of up to 1 bar overpressure.

Exhaust and Flue gas Recuperators

Unit to recover excess heat from exhaust and/or flue gas of production processes.

PUMPING StATIONS

Unit for circulating liquids (e.g. water/ glycol) in heat recovery systems.

Heat Recovery Systems

System to economically recover process or flue gas heat using a circulation loop or via direct heat transfer.

Pillow Plate, Bare Tube and Further Solutions

Process Therm

Pillow plate type heat exchanger with integrated CIP (Cleaning in Place) system

Therm-X

Self-cleaning pillow plate heat exchanger with rotating brushes for unclean liquids

TP-HEX

Pillow plate heat exchanger for challenging liquid-to-liquid heat transfer applications

Gas-to-Gas

Gas-to-gas heat exchanger solutions, suitable for aggressive, dust or particle loaded gaseous media

FILTER UNITS

Unit to filter process air for industrial processes - custom made according to the process demands

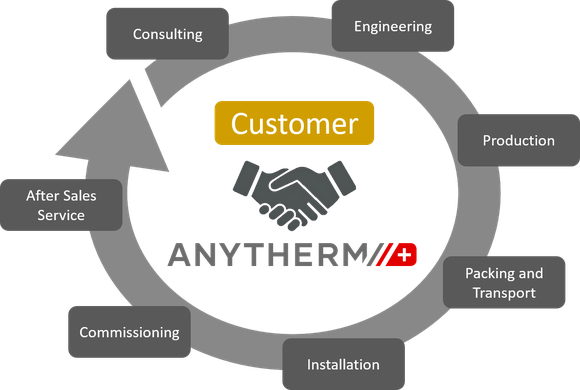

Services

Our heat exchange services cover the whole process within the scope of heat exchange, heat recovery and energy efficiency improvement projects: from consulting before project initialization to installation on site up to after sales service.

Even though being an established technology, heat exchanging applications can be challenging regarding production implementation or when having polluted media. Based on the profound and reliable knowledge in advanced heat exchanger technology, we can analyse the optimisation and heat recuperation potential (incl. economic analysis) of your site and provide hands-on concepts for implementation.

References

Find below a selection of references from Anytherm projects of the last two years.

More informations on our versatile, worldwide projects and its impressive process air handling, heat transfer, dehumidification and heat recovery units can be found in the References section.

Technology

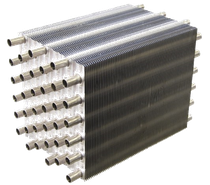

Finned tubes

- Tubes mechanically expanded into self-spacing collars die-formed on the fins

- Finned block technology: Higher stability than tubes with separated fins and excellent heat transfer characteristics

- Waved profile fin structure providing high heat transfer coefficients to aim for the best cost/performance ratio

Pillow plates

- Two plates, spot welded together, sealed with weldings along the contours of the plates, hydraulically expanded to designed channel height

- Adaptability: Plate thickness and spot pattern dimensioned as a function of the design pressure; channel height and space between the pillow plates determined by flow and pressure drop specifications

- Very easy to clean solution, with high efficiency due to large surface to volume ratio in combination with a turbulent flow pattern and low pressure drops

Impressions

Get impressions of Anytherms high quality products with pictures from everyday production life.

Heat Exchange, Heat Recovery and Energy Efficiency - Because Any Therm Matters!