Sorptionsentfeuchter

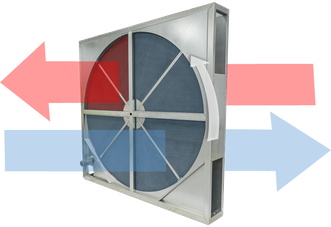

Regeneration Air Outlet:

- The regeneration air in couterflow dries out and therefore «regenerates» the sorption wheel

Process Air Inlet:

- Up to 200’000 kg/h

- Usually flows through 180° up to 270° sector (as shown) of the sorption wheel

Regeneration Air Inlet:

- Temperatures in the range 120-170°C

- Usually flows through 90° (as shown) up to 180° sector of the sorption wheel

Process Air Outlet:

- Can be dried down to below 2 g/kg humidity without condensation

Main Features

- Unit to dehumidify process air without condensation

- Making use of the (ad)sorption process defined as the accumulation of molecules on a surface

- Core part is the so called sorption wheel which accumulates (adsorbs) the water dissolved in the process air on its surface

- Many additional components can be included in the sorption units (see optional equipment) according to the client specification and request

Materials And Characteristic Values

- Sorption wheel (also known as desiccant wheel): silica gel

- Rotation: maintenance-friendly chain drive with a constant speed of around 10 to 15 rotations per hour

- Seals: radial and axial seals (as shown on the right) to separate the two counter flows from each other and from the surroundings

- Housing: Stainless steel with mineral wool insulation

Optional equipment

- Regeneration air heater (e.g. steam)

- Pre-cooler (condensation dehumidifier) for higher drying capacity

- Air cooler after the sorption wheel (as the air gets heated up by the drying process)

- Heat recovery systems

- Sound attenuators

- Filter stages for both process and/or regeneration air

Customized according to client specification and request

Get impressions about our high quality products by viewing the photographs shown in the home section of our website.